Hastelloy G30

Hastelloy G30 is a nickel base alloy with high chromium content. Compared to most other nickel – and iron-based alloys, it has excellent corrosion resistance to mixed environments of commercial phosphoric acid and many highly oxidizing acid media, such as nitric/hydrochloric acid, nitric/hydrofluoric acid and sulfuric acid. G30 alloy can prevent the formation of grain boundary precipitation in welding heat affected zone, so its welding products are suitable for various chemical treatment projects.

Technical standard: ASTM B366/ASTM B581/ASTM B582/ASTM B619/ASTM B622

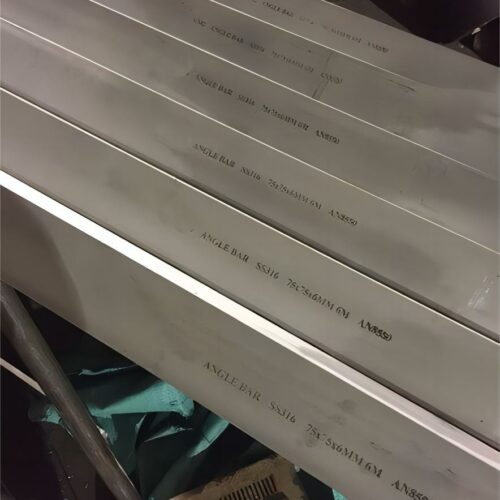

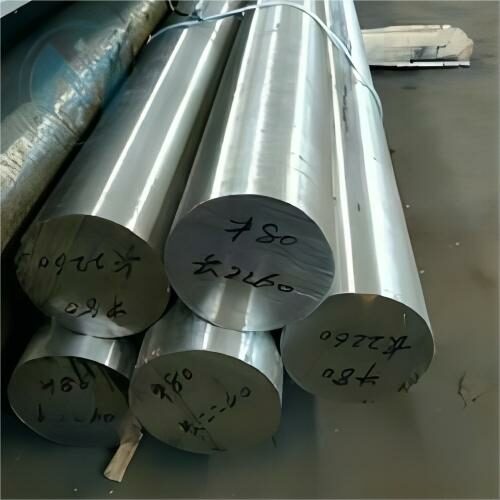

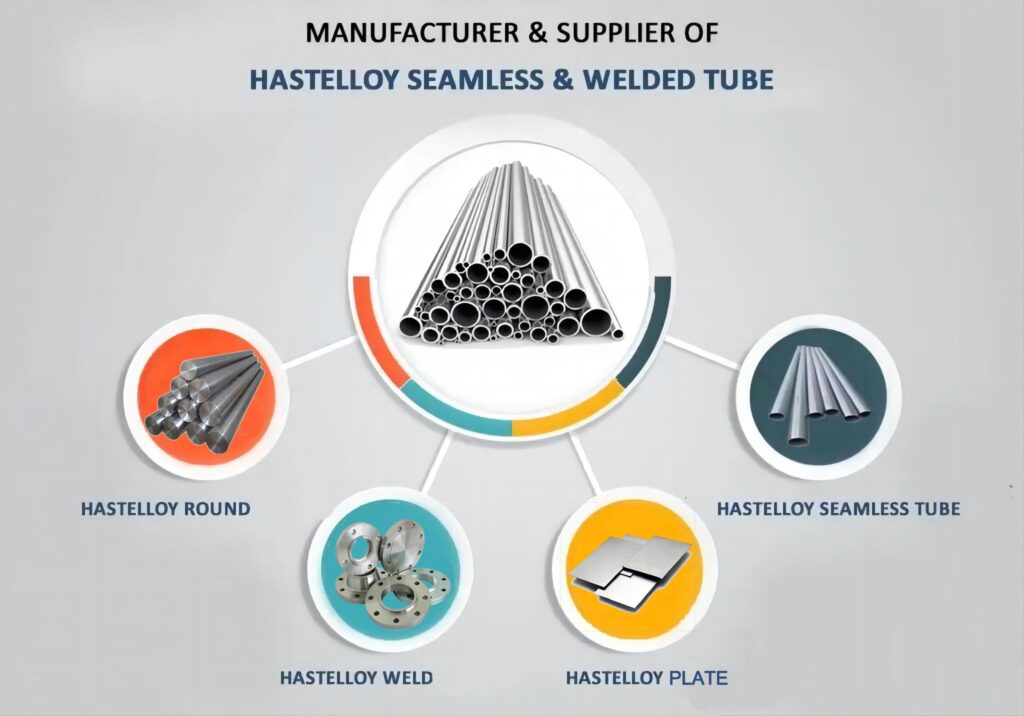

Product: pipes,plates,bar,fittings

Chemical component:

| Cr | Mo | Mn | Cu | C | Si | P | S | Iron | Tungsten | Columbium+tantalum | |

| Alloy N06030 | 28-31.5 | 4.0-6.0 | 1.5 | 1.0-2.4 | 0.03 | 0.8 | 0.04 | 0.02 | 13.0-17.0 | 1.5-4.0 | 0.3-1.5 |

1.Hastelloy G30 is widely used in phosphoric acid equipment, sulfuric acid equipment, nitric acid equipment, nuclear fuel reprocessing, nuclear waste disposal, pickling, petrochemical products, fertilizer production, pesticide production and gold mining. Hastelloy G30 has excellent tolerance to hydrofluoric acid/nitric acid mixtures used in applications such as stainless steel pickling. Hastelloy G30 is better tolerated in industrial phosphoric acid than other nickel-based or iron-based alloys. It is increasingly used as acid evaporator in fertilizer industry.

2.Comparison of corrosion resistance in industrial phosphoric acid: The corrosion resistance of Hastelloy G30 Hastelloy, G alloy and 625 alloy in industrial phosphoric acid is as follows. Corrosion resistance of commercial phosphoric acid is determined by a number of factors, including concentration, temperature, impurities, and phosphate ore source. The corrosion rate of phosphoric acid with the same concentration obtained from different phosphate sources may vary greatly. Therefore, corrosion tests are measured in different sources of phosphoric acid, and the corrosion resistance of G-30 alloy is expressed as a function of the corrosion rate of G alloy and 625 alloy, respectively. The corrosion resistance of G-30 alloys is generally 2-10 times stronger than that of G alloys and 625 alloys for the same acids at corrosion rates of 0.025-2.5 mm.