INFORMATION

Inconel 600 alloy technical parameters

| Inconel 600 (UNS N06600) | |||||||||

| Summary | Nichcr alloy has good oxidation resistance at high temperature. Resistance to chloride ion stress corrosion cracking, high purity water corrosion and alkali corrosion. Used for heating furnace components, chemical and food industries, nuclear engineering and ignition electrodes. | ||||||||

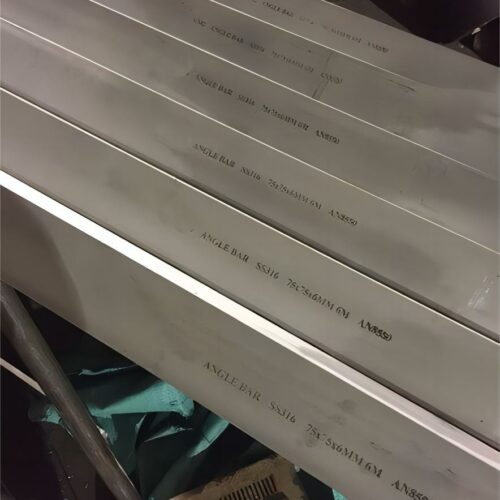

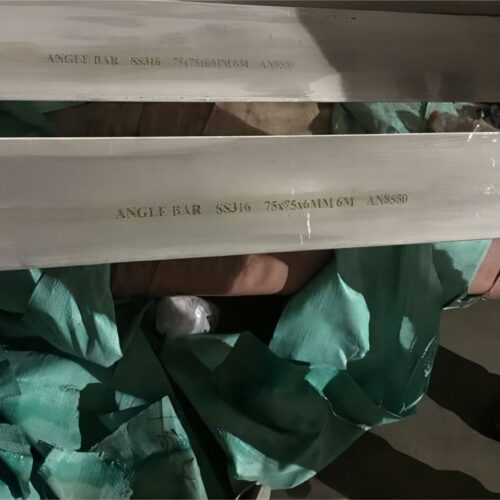

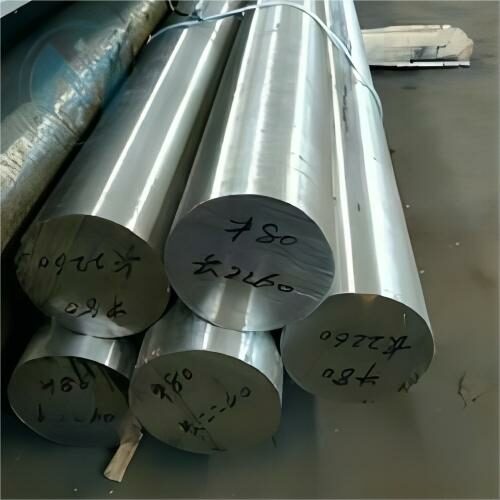

| Product | Pipe, plate, strip, round bar, flat bar, forgings, wire, profile, extruded parts. | ||||||||

| Chemical composition | Min . | Max. | Min. | Max. | Min. | Max. | |||

| Ni | 72.0 | Cu | 0.5 | C | 0.15 | ||||

| Cr | 14.0 | 17.0 | Co | Si | 0.5 | ||||

| Fe | 6.0 | 10.0 | Al | P | |||||

| Mo | Ti | S | |||||||

| W | Mn | 1.0 | N | ||||||

| Physical

constant |

Density,g/cm ³ 8.47 | ||||||||

| Melting Range, ℃ 1354-1413 | |||||||||

Microstructure

Inconel 600 is a face-centered cubic lattice structure, stable austenite solid solution gold.

Characters

1.Good corrosion resistance to reduction, oxidation and nitriding media.

2.Excellent has good stress corrosion cracking resistance at room temperature and high temperature.

3.Super resistance to dry chlorination and hydrogen chloride gas corrosion properties;

Corrosion Resistance

The chemical composition of lnconel 600 alloy makes it resistant to corrosion in a variety of environments. A certain amount of chromium in the alloy makes its corrosion resistance better than that of industrial pure nickel in the oxidation environment, and the higher nickel content In addition, it can maintain considerable corrosion resistance in the original environment. The nickel content of the alloy also makes it have excellent corrosion resistance to alkali solutions.