Stainless steel is a type of steel that contains a minimum of 10.5% chromium. This element provides corrosion resistance and durability, making it ideal for a variety of applications. 316L stainless steel is a specific type of stainless steel that is commonly used in many industries. Here’s everything you need to know about 316L stainless steel sheet and its applications.

Stainless steel is a type of steel that contains a minimum of 10.5% chromium. This element provides corrosion resistance and durability, making it ideal for a variety of applications. 316L stainless steel is a specific type of stainless steel that is commonly used in many industries. Here’s everything you need to know about 316L stainless steel sheet and its applications.

What is 316L Stainless Steel?

316L stainless steel is a type of stainless steel that contains molybdenum, which enhances its corrosion resistance. It is also low-carbon, which makes it less susceptible to sensitization and corrosion in high-temperature environments. 316L stainless steel is often used in marine applications because it is resistant to saltwater corrosion.

Properties of 316L Stainless Steel Sheet

316L stainless steel is a type of austenitic stainless steel that contains a low carbon content, making it suitable for welding applications. It is a popular choice for various industries, including the medical and pharmaceutical industries due to its corrosion resistance, strength, and durability. Here are some properties of 316L stainless steel sheet:

- Corrosion Resistance: 316L stainless steel sheet is highly resistant to corrosion in a wide range of environments, including both acidic and alkaline conditions.

- Strength: 316L stainless steel sheet has high tensile and yield strength, making it suitable for use in applications that require strength and durability.

- Heat Resistance: 316L stainless steel sheet is able to withstand high temperatures without losing its strength and properties, making it suitable for use in high-temperature environments.

- Weldability: 316L stainless steel sheet is easy to weld and can be welded using standard welding techniques, making it suitable for use in a variety of applications.

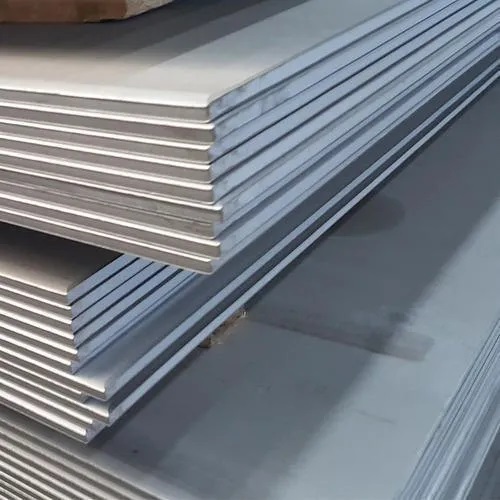

- Appearance: 316L stainless steel sheet has a polished, shiny finish that is aesthetically pleasing and suitable for use in decorative applications.

- Hygiene: Due to its high resistance to corrosion and ease of cleaning, 316L stainless steel sheet is commonly used in the medical and pharmaceutical industries where hygiene is critical.

Overall, 316L stainless steel sheet is a versatile material that is suitable for use in a variety of applications due to its corrosion resistance, strength, durability, and other properties.

Applications of a 316L Stainless Steel Sheet

316L stainless steel is a popular material due to its excellent corrosion resistance, high strength, and good formability. Here are some common applications of a 316L stainless steel sheet:

- Medical devices: Due to its biocompatibility and resistance to corrosion, 316L stainless steel is widely used in the manufacture of medical devices such as surgical instruments, orthopedic implants, and stents.

- Marine industry: 316L stainless steel is commonly used in the marine industry due to its resistance to seawater corrosion. It is used to make marine fittings, propeller shafts, and other components.

- Chemical processing: 316L stainless steel is often used in chemical processing equipment because of its resistance to corrosion by acids, alkalis, and other chemicals. It is used in the manufacture of chemical storage tanks, pipes, and valves.

- Food processing: 316L stainless steel is widely used in the food processing industry because of its excellent resistance to corrosion and high-temperature environments. It is used to make equipment such as conveyor belts, mixing tanks, and food processing machinery.

- Aerospace industry: 316L stainless steel is used in the aerospace industry due to its high strength and resistance to corrosion. It is used to make components such as aircraft engines, fuel tanks, and structural parts.

- Architecture: 316L stainless steel is often used in architectural applications due to its aesthetic appeal and resistance to corrosion. It is used to make components such as handrails, fittings, and decorative panels.

- Automotive industry: 316L stainless steel is used in the automotive industry because of its high strength and corrosion resistance. It is used to make components such as exhaust systems, mufflers, and catalytic converters.

Overall, 316L stainless steel is a versatile material that is widely used in many industries due to its excellent corrosion resistance, high strength, and good formability.

Factors to Consider When Purchasing a 316L Stainless Steel Sheet

There are several factors to consider when purchasing a 316L stainless steel sheet, including:

- Grade: The grade of the stainless steel sheet is an essential factor to consider when buying. 316L stainless steel is a low carbon version of 316 stainless steel, which provides improved corrosion resistance, especially in chloride environments.

- Size and Thickness: Stainless steel sheets come in various sizes and thicknesses. Consider the size and thickness of the sheet you need for your project.

- Surface Finish: Stainless steel sheets come in different surface finishes, such as brushed, polished, or matte. Consider the application and aesthetic appeal of the finish.

- Corrosion Resistance: One of the primary benefits of stainless steel is its corrosion resistance. Ensure that the 316L stainless steel sheet you purchase is suitable for the application, and its corrosion resistance is appropriate for the environment.

- Certification: Check for certifications and quality assurance from the manufacturer or supplier to ensure that the 316L stainless steel sheet meets industry standards.

- Cost: The cost of the 316 stainless steel sheet can vary depending on the size, thickness, and grade. Consider your budget and compare prices from different suppliers to get the best deal.

- Application: Finally, consider the application of the 316L stainless steel sheet. Ensure that the sheet you purchase is suitable for your intended use and can withstand the conditions of the environment where it will be used.

Where to Find the Best Quality 316L Stainless Steel Sheets?

There are several places where you can find high-quality 316L stainless steel sheets. Here are a few options:

- Local metal suppliers: You can find stainless steel sheets from local metal suppliers or fabricators in your area. Look for suppliers who specialize in stainless steel and have a good reputation for quality and customer service.

- Online metal suppliers: Online suppliers like OnlineMetals.com, MetalsDepot.com, and Industrial Metal Supply offer a wide range of stainless steel sheet options, including 316L, and can deliver directly to your doorstep.

- Manufacturers: If you need large quantities of 316L stainless steel sheets, it may be best to purchase directly from a manufacturer. Look for reputable manufacturers with a proven track record for quality.

- Trade shows: Attending trade shows or industry events can be a great way to connect with suppliers and manufacturers of stainless steel sheets, including 316L. You can also learn about the latest products and technologies in the industry.

When purchasing stainless steel sheets, it’s important to consider the thickness, finish, and size you need for your specific application. Be sure to do your research and compare prices and options from different suppliers to find the best quality 316L stainless steel sheets for your needs.

Conclusion:

Based on the information available, it appears that starting a project with quality assured 316L stainless steel sheets can be a wise choice. 316L stainless steel is a durable and corrosion-resistant material that is often used in applications where strength, longevity, and hygiene are important. It is also a versatile material that can be fabricated into a variety of shapes and sizes to suit different project needs.

Choosing quality assured 316L stainless steel sheets ensures that you are getting a product that meets high standards for purity, consistency, and performance. This can help to ensure that your project is completed on time, within budget, and with minimal issues or setbacks.

However, it is important to note that the suitability of 316 stainless steel sheet for a particular project will depend on various factors, such as the specific application, operating conditions, and regulatory requirements. Therefore, it is advisable to consult with a qualified engineer or materials expert before making any decisions regarding the use of 316 stainless steel sheets in your project.