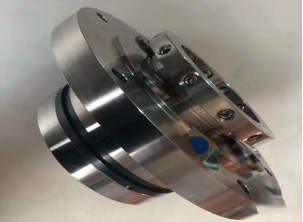

The mechanical seal can also be called the end face seal, which is perpendicular to the end face of the rotation axis. Under the action of the fluid pressure on the end face and the external elastic force of the compensation machine, it relies on the auxiliary seal to keep fit with the other end and make relative sliding to prevent the pump from delivering the medium. Due to the aging and wear of the seal during the operation of the pump, it is relatively rare for the mechanical seal to leak suddenly. Let’s talk about the reasons for the sudden leakage of the mechanical seal of the multi-stage pump.

Reasons for sudden leakage of the pump mechanical seal:

1. When the mechanical seal is held in the pump for a long time, it will be damaged to a certain extent, resulting in leakage. Evacuation and cavitation of the pump may also cause sudden leakage of the mechanical seal.

2. The sudden failure of the mechanical seal may be due to the fact that the actual output of the multi-stage pump medium is too small, resulting in a large amount of medium liquid in the pump continuously circulating and the temperature in the pump increases, which leads to the vaporization of the pumped medium and the sudden failure of the mechanical seal.

3. The large return flow rate of the water pump medium will also cause damage to the mechanical seal. If the return flow rate of the water pump exceeds the expected value, there will be sediment at the bottom of the container on the suction pipe side of the pump. After the sediment enters the pump, it will damage the mechanical seal and cause the mechanical seal to suddenly fail. leakage.

4. If the water pump has not been used for a long time, it is not in a normal operation state, and the manual cranking is not performed before starting the water pump again, which will cause the friction pair of the mechanical seal to stick, which will also cause damage to the end face of the mechanical seal, resulting in leakage.

5. The compatibility between the mechanical seal material and the medium conveyed by the pump is poor, and the medium is relatively corrosive, polymerizable, and gelatinous, which damages the sealing surface of the mechanical seal and causes leakage of the mechanical seal.

6. Excessive temperature differences in the working environment of the mechanical seal, frequent changes in working conditions, or sudden shutdown of the pump will also cause mechanical seal leakage. The mechanical seal suddenly fails during normal operation and leakage will cause relatively large damage to the pump equipment and even serious damage. Therefore, it is recommended that water pump users must regularly maintain the water pump to reduce water pump accidents.